Fire break out causes huge damage to the property and the life of occupants. Among many fire protection tools, fire resistant is one of them.

Fire resistant paint has the properties that reduce the burning rate and prevent fire spread. It has the properties that decrease the burning rate and prevent the spread of fire. They are the widely used fire protection solution in factories, commercial buildings and residential homes.

Fire resistance is the amount of time a structural component of a building will remain intact or safe.

Benefits of using fire resistant paint

- Fire protection: One of the significant benefits of using fire resistant paint is to provide higher level of protection from fire. Fire breakout can be dangerous. The fire resistant paint provides safety against fire as they reduce the burning rate and prevent fire spread.

- Suitable for many surfaces: The best quality fire resistant paint can be used in variety of surface. No matter the type of surface, the paints can be used to provide fire protection.

- Added protection: Fire resistant paints can be used in products where one can add a level of protection internally. The special paint products are coated onto the ceilings and walls to add an extra level of protection.

- Easy to apply: Fire resistant paint products are easy to apply during home renovation project or during construction as normal paints. An added benefit they offer is they are coated on top of other types of paints. This makes them easy to apply and one will not have to remove old paint coats first.

- Aesthetics: They are available in many colors and finishes that mean they can be used to match the existing color scheme of the building. They help maintain the appearance of the building while providing added fire protection.

- Cost-effectiveness: The initial cost of using intumescent paint may be higher than other fire protection solutions but it is a budget-friendly solution in the long run. The paint provides high level of protection and does not need to be replaced as often as other fire protection systems.

- Maintenance: Fire resistant paints require low maintenance and do not need special care or upkeep to maintain their effectiveness. To maintain the integrity of the coating, regular inspections and touch-up painting may be required.

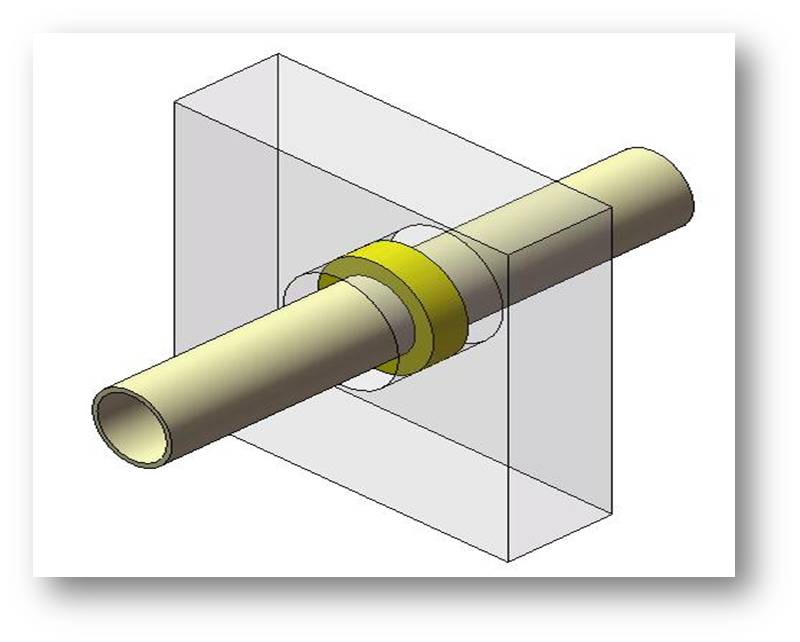

How to fire resistant paint work?

Fire resistant paint or intumescent paints react to heat created by fire and swell up to create an insulation layer. This layer will protect the building long enough to allow safe evacuation.

Fire resistant paint – intumescent paint is a highly effective fire protection shield. Whether looking to protect home or business, this paint provides added fire protection that is required to keep building and the occupants safe.

Protect your property, assets and lives of your loved ones and employees with fire resistant paint!